Screw Feeders

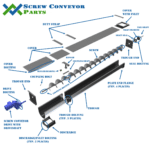

A screw feeder is a versatile, compact and economical metering device for powder bulk solids. What distinguishes a screw conveyor from a screw feeder? A screw feeder is used to meter, or set the flow rate, to other pieces of conveying and process equipment from a hopper, silo or bulk bag. The inlet of a screw feeder, whether square, rectangular or round is flooded with bulk material at all times and therefor has to be specifically designed for this condition. The distance between the flights (pitch), diameter and speed (RPM) of the screw feeder determine how much bulk material is fed out of the bin over time and can be adjusted by varying any of these parameters. Screw feeders meter product by volume and are often referred to as volumetric feeders.

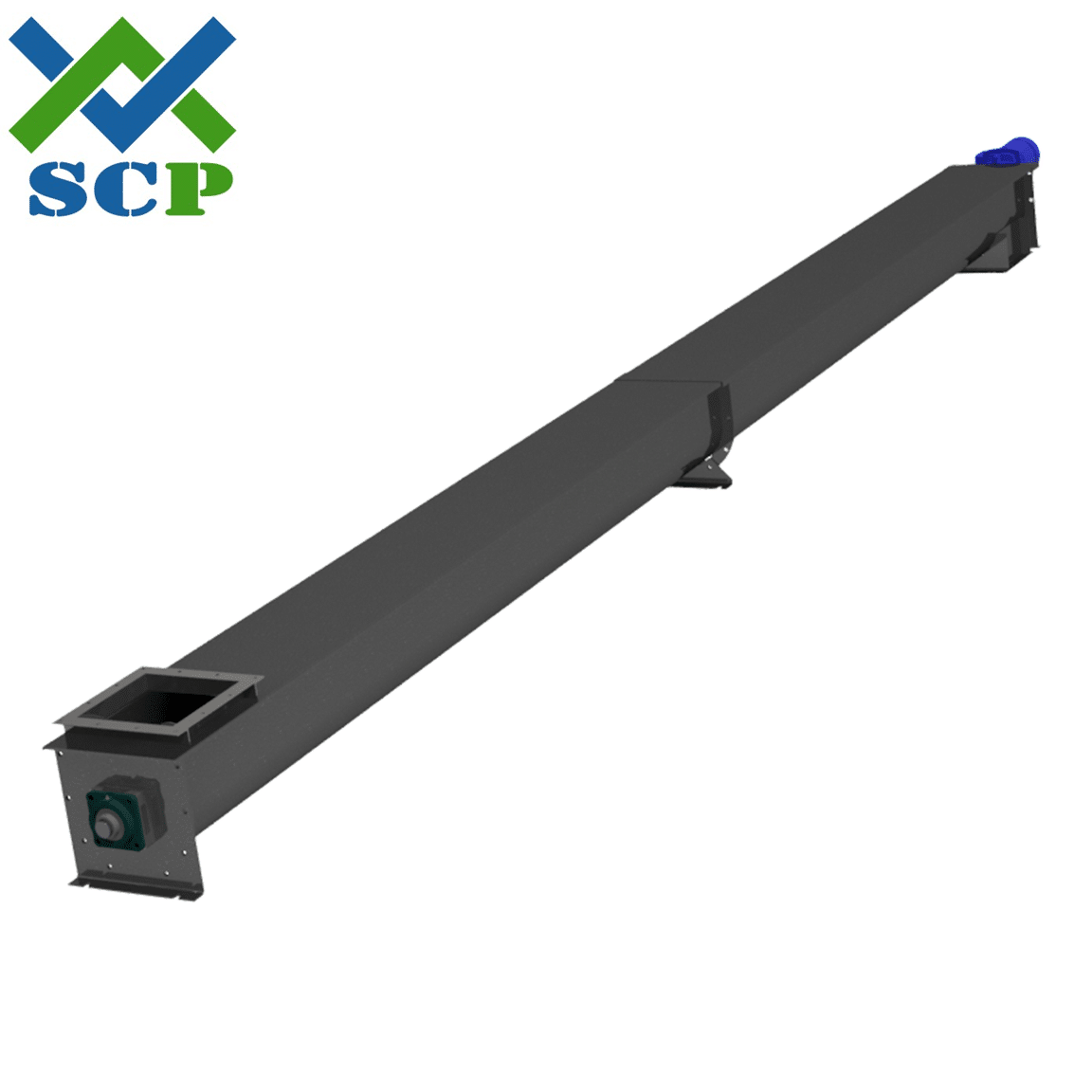

A screw feeder is the most versatile and customizable bulk material metering solution available. With a wide ranges of standardized and stocked components, screw feeders can be easily and affordably customized to fit any application. Even completely custom solutions are standardized for ease of manufacturing, assembly and maintenance. Screw feeders can be designed to be horizontal or inclined and are specifically matched in size, speed and horsepower to the application. Screw feeders also offer the benefit of being completely enclosed for dust/vapor containment and safety. Since a screw feeder is completely enclosed with only a smooth low speed shaft exposed the risk to operators is very low. Even the shafts can be covered to offer a completely enclosed and worry free solution. Screw feeders can be manufactured in a wide variety of materials with carbon steel being the most common. Other materials of construction include 304 stainless steel, 316 stainless steel, T1 steel, abrasion resistant steel and even exotic alloys like duplex stainless steel and titanium.

Custom Designed Screw Feeders for Any Application

SCP offers a full line of screw feeders custom designed and built to fit any application. SCP uses a hybrid approach to screw feeder design by using as many low cost, high volume sock components as possible, blended with unique and engineered accessories such as the SCP Master Seal to offer a low-cost and reliable solution for any bulk material metering need. SCP has access to a vast inventory of stock screw conveyor and feeder parts and components along with the largest manufacturing capacity in the country. SCP employees well-renowned feeder and process experts to assist with every aspect of screw feeder design. Not only does SCP offer the best solution for every application but does so with an acute awareness of the price vs. benefit. It is not just about offering the best solution, but offering the right solution for the application AND Budget.

Browse our website for a host of screw feeder articles, catalogs and videos. After the research is done, SCP offers every spare part needed to keep a screw feeder running and even complete pre-engineered screw conveyor kits available for immediate shipment. As always, our sales engineers are available to help with any application. Contact us at 682-231-1228 or [email protected]

Gallery

Screw Feeder Resources

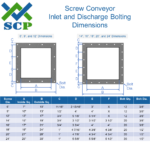

Screw Feeder Drawings

Suggested Products for Screw Feeders

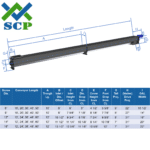

9" Diameter x 30ft-0in Screw Conveyor Kit with 2" dia shafts and Wood Hanger Bearing

$4,403.0012" Diameter x 12ft-0in Screw Conveyor Kit with 3" dia shafts

$3,354.0014" Diameter x 48ft-0in Screw Conveyor Kit with 3" dia shafts and Hard Iron Hanger Bearing

$10,654.0016" Diameter x 48ft-0in Screw Conveyor Kit with 3" dia shafts and Wood Hanger Bearing

$10,751.00