Screw conveyor trough loading at 15%, 30% and 45%

Category: Screw Conveyor Design

Screw conveyors are standardized through CEMA based on the screw outside diameter and the shaft outside diameter making these the 2 most important facts to know about a screw conveyor when sizing, designing or buying replacement parts.

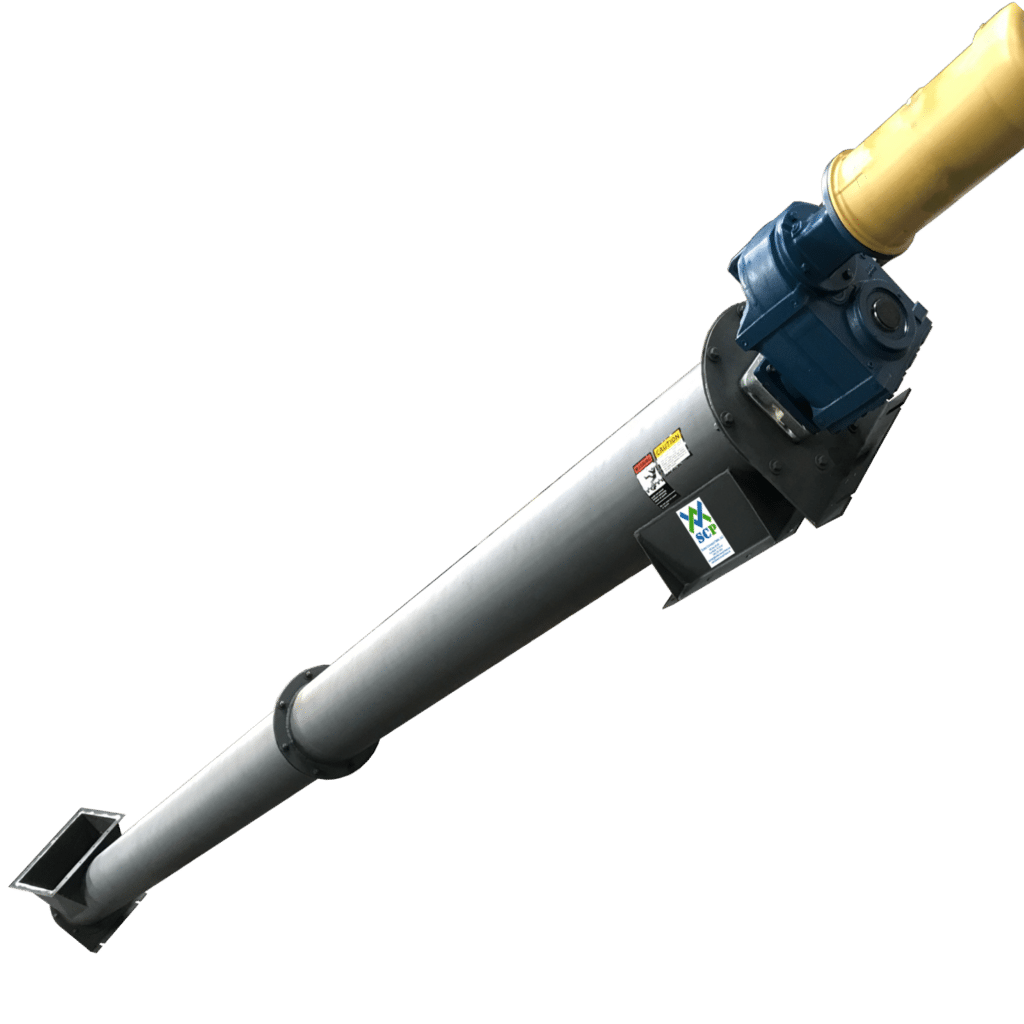

The screw conveyor drive, also called the reducer, refers to the motor/gear reducer assembly used to drive the screw conveyor.

One of the areas we pride ourselves on is designing screw conveyors that both perform well and are economical. How do we do that? We use all stock parts, or modified stock parts. Doing this ensures the cost is kept down, leadtimes are shorter and long term maintenance is easier due to the availability of replacement parts.

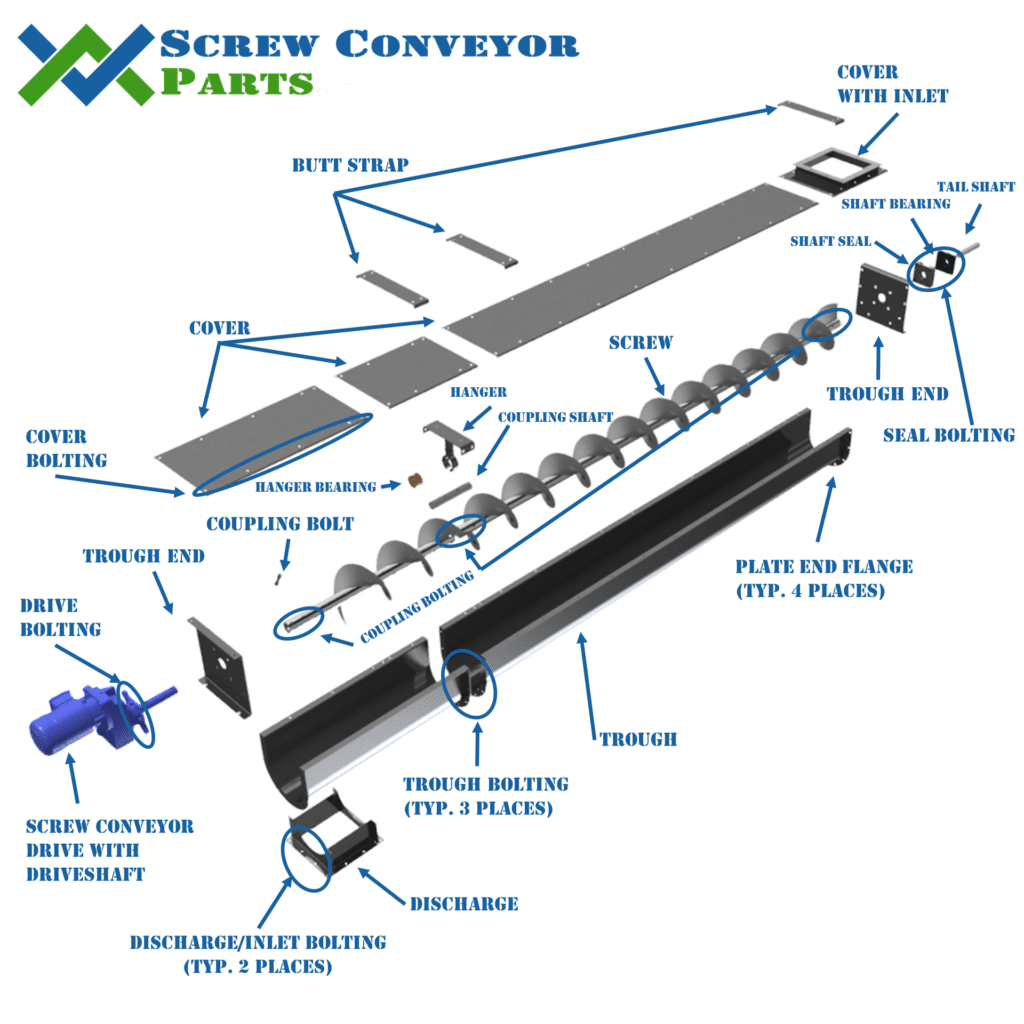

Diagram of an exploded screw conveyor with all parts labeled.

Screw conveyors are extremely versatile and therefore called to do a lot in a modern bulk material handling process.

Screw conveyors come in many sizes, shapes and configurations and function in very similar ways.

A screw conveyor is a versatile machine capable of fitting a wide verity of applications and moving an almost infinite range of bulk materials.

These 3 things to remember when designing a screw conveyor or screw feeder. If you want a screw conveyor that will last forever keep these words in mind.