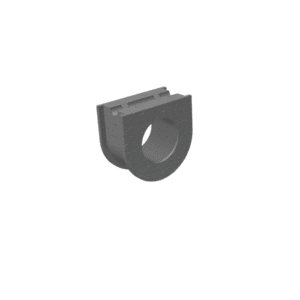

A hard iron hanger bearing is used to support a long screw. A screw conveyor is a versatile conveyor with one main limitation; the length. The longer the screw conveyor gets the longer the screw must be. If the screw gets too long, it can start dragging on the screw conveyor trough and eventually wear a hole. To help the screw span the long distances needed for many conveying applications a hanger and hanger bearing are used. A hanger bearing is usually a friction bearing, meaning it is a metal shaft riding on some type of solid hanger bearing.

Hard Iron

Hard Iron is one of many choices of materials available for a hanger bearing. (Click HERE for more about different materials) Hard iron (Ni-Hard) is a white cast iron formulated with nickel and chromium and suitable for low impact, sliding abrasion for both wet and dry applications. Hard iron has a minimum hardness of 550BHN.(1) A hardened shaft is required with a hard iron hanger bearing to ensure the hanger bearing wears and not the shaft. Due to its extreme toughness, hard iron is well suited for the most abrasive environments. Lubricant can be added to help extend the life of the bearing and reduce noise.

Application

Hard iron hanger bearings are stocked in both CEMA style 220/226 and 216 and up to 3 7/16″ diameter shaft size. Many manufacturers also stock larger shaft sizes, too. Hard iron hanger bearings are tough and well suited for conveying environments like sand, limestone and cement. As with any other hanger bearing care should be taken to make sure regular inspections are conducted and convenient access is available for periodic replacement. The life of a hard iron hanger bearing is dependent on a lot of factors and a thorough predictive maintenance program should be implemented to ensure downtime is kept to a minimum.