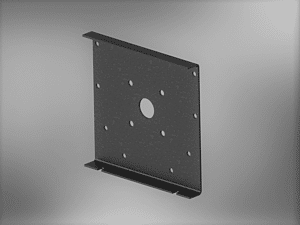

The trough end on a screw conveyor is the end plate that supports the screw, bearing and shaft seal. Like most screw conveyor parts, the term has some loose affiliation with the agricultural industry. The trough, or screw housing, being similar to that of a pig trough, so the end would just be referred to as the trough end. Some people call it the end plate and there are a few other terms that have been thrown around, too.

Selecting the proper screw conveyor trough end is very important. It has a big job to do because it holds the shaft bearing that supports the screw. This creates a tremendous amount of force on the trough end and is why the trough end is usually made of much heavier plate than the rest of the screw conveyor. As the length of the screw becomes longer, the forces on the trough end get larger and larger and even more emphasizes is placed on the importance of this piece of the screw conveyor.

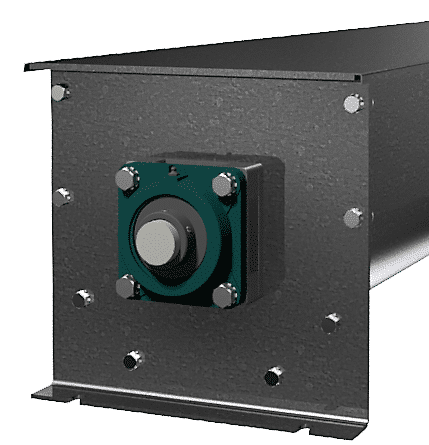

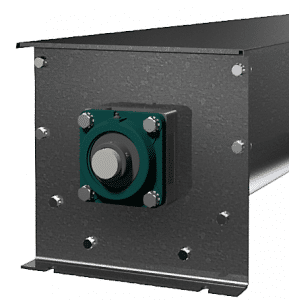

In addition to the bearing, the trough end supports one of the most problematic areas of a screw conveyor, the shaft seals. They are the most likely to wear and allow contaminants into the atmosphere. Traditional seal options for screw conveyors use CEMA trough ends, but higher end seals require specially built trough ends to accommodate their unique mounting requirements.

The standard CEMA trough end used by all screw conveyor manufacturers is adequate for many applications. It can accommodate a flanged bearing and flanged shaft seal and is strong enough to support most standard screw diameters, shaft sizes and is good up to standard screw lengths. The CEMA trough end can also support a screw conveyor drive for the drive end. The next option would be the pedestal trough end. This can be either an integral pedestal, like the one shown in the picture, or can be a bolt on pedestal. Both styles allow the use of an external bearing and a variety of shaft seals. In addition, the pedestal trough end allows for the use of more traditional drives, with the addition of the flanged or torque arm bracket.

Selecting the proper trough end for your application can be one of the most important decision in ensuring the screw conveyor has a long and productive life. The chart below will help in selecting the correct trough end and required accessories.

| Shaft Seal | Drive Type | |||

| Screw Conveyor Drive | Torque Arm Drive | Flanged Drive | ||

| Plate Seal | TE1 | TE2 | TE3 | |

| Waste Pack Seal | TE1 | TE2 | TE3 | |

| Flanged Gland Seal | TE3 | TE2 | TE3 | |

| Packing Gland Seal | TE3 | TE2 | TE3 | |

| Split Gland Seal | TE3 | TE2 | TE3 | |

| Special Seal | TE3 | TE2 | TE3 | |

TE1 – This drive and shaft seal option require a CEMA trough end.

TE2 – This drive and shaft seal option require a CEMA trough end with a torque arm attachment

TE3 – This drive and shaft seal option require a CEMA trough end with a flanged drive attachment.