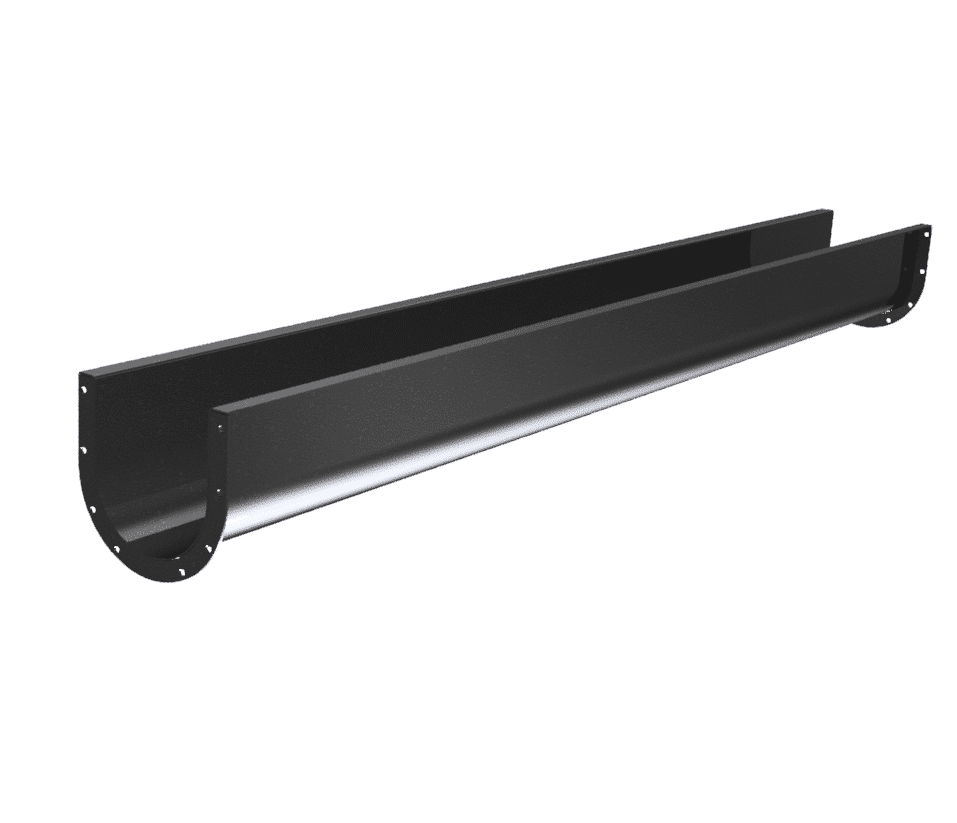

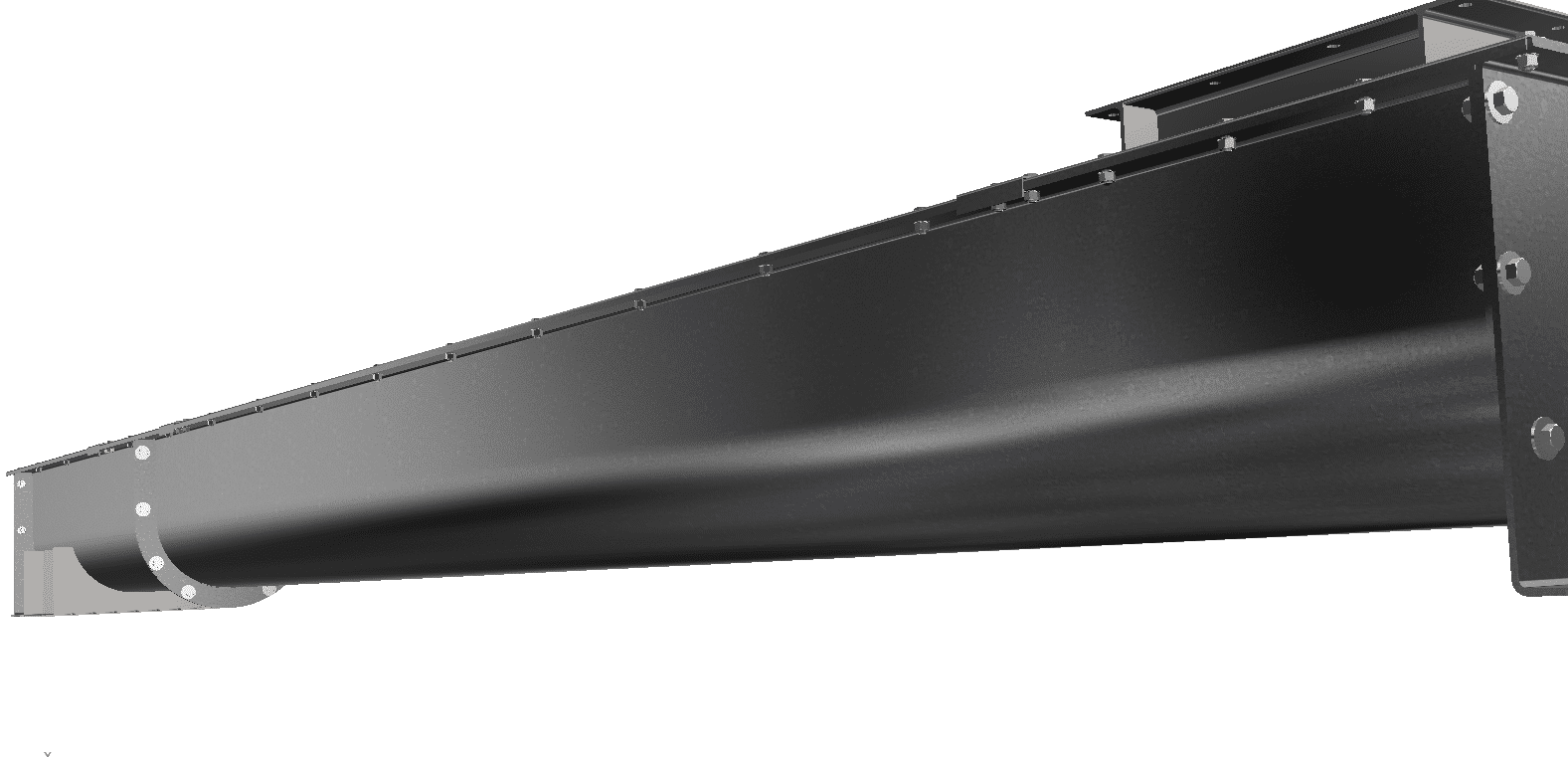

Selecting the proper screw conveyor trough is very important because the material being conveyed is enclosed by it. The conveyed material induces abrasive wear and can eventually wear a hole in the trough, posing a major safety concern from both the exposure to the moving screw and the exposure of the material in the trough to the atmosphere. Most troughs come in standard lengths of up to either 10ft or 12ft and are usually made of some light gauge material like 12GA or 7GA mild steel (A36). The shape of the trough is important, too. The most common configuration is the U-shaped trough, but round, flared and rectangular troughs are common, too.

In the case of long screw conveyors with multiple screws connected using hanger bearings, the trough also support the weight of the screw, in addition to conveying the material. Because of this, the trough rigidity and alignment are important to the long term success of the screw conveyor. In most cases, a standard trough is rigid enough for a standard screw and hanger. If a nonstandard length screw is used, the trough must be evaluated to see if it can support the heavier weight of the screw. If the screws are being supported with hanger bearings then the alignment of the trough will influence the alignment of the screws. Screws that are out of alignment can rub the trough, fatigue the shaft and/or cause accelerated wear of the hanger bearing.

Replacement of the trough is usually pretty easy. There are 6-12 bolts located at each end that once removed (and the screw supported) the trough can be removed and replaced. Patch kits are also available if a hole wears in a specific area. Patch kits are made of abrasion resistant material and conform to the outside shape of the trough.

Selecting the proper trough for your application can be one of the most important decision in ensuring the screw conveyor has a long and productive life. With so many options, it can be hard to know which ones will be right for the application and how much impact the option will have to the cost of the trough. The following factors break down the major considerations when selecting a screw conveyor trough. This information is also useful in illustrating how various options can have huge impacts in the cost of a screw conveyor.

Cost impact guide.

$ – Stock Trough

$$ – Adds about 50% to the trough cost

$$$ – Adds about 100% to the trough cost

$$$$ – Adds about 150% to the trough cost

$$$$$ – Adds more than 150% to the trough cost

Shape

The shape of the trough is the first decision the buyer has to make.

- “U” – The U-shaped screw conveyor trough is the most common trough shape and is suitable for almost all applications. It allows complete access to the screw and hangers by removing the cover; making maintenance of the screw conveyor much less time consuming

- Cost Impact – $

- Flared – The flared screw conveyor trough is used for applications where large, bulky material may be conveyed above the screw or where a larger top opening of the trough is required. These applications include rendering and agricultural processing centers for fruits and vegetables.

- Cost Impact – $$$

- Tubular – The tubular screw conveyor trough is useful for inclined applications (>15°) because the ID of the tube is ½” from the OD of the screw and helps to prevent the material from falling back over the flight as it is conveyed up the incline. The tubular trough is also useful for conveying sticky materials because the close ID/OD minimizes area for material to collect. The tubular trough is available as a one-piece “O” shape or as a two-piece bolt together “C” assembly.

- Cost Impact – $$ (“O” Shape) – $$$$ (“C” Shaped)

- Rectangular – The rectangular screw conveyor trough is used in abrasive applications. The rectangular section allows material to collect around the screw and form a barrier between it and the housing. This barrier protects the housing from abrasive wear.

- Cost Impact – $$$

Thickness

The thickness of the trough helps provide rigidity and fights abrasive wear. For moderately and heavily abrasive materials going thicker helps prolong the life of the screw conveyor.

- Light (14GA, 12GA, 10GA) – These lighter gauge screw conveyor troughs are sufficient for mildly abrasive materials and trough sizes trough about 18″. Example materials to be conveyed in light screw conveyor troughs include Ice, Cornmeal, Distillers Grain, and Flour.

- Cost Impact – $

- Medium (7GA, 3/16″, 1/4″) – These medium gauge screw conveyor troughs are sufficient for moderately abrasive materials and trough sizes trough about 24″. Example materials to be conveyed in medium gauge screw conveyor troughs include Soybeans, Crushed Limestone, and Raw Peanuts

- Cost Impact – $$

- Heavy (3/8″ and 1/2″) – These heavy steel screw conveyor troughs are sufficient for heavily abrasive materials and all trough sizes above about 12″. Example materials to be conveyed in heavy gauge screw conveyor troughs include Sand, Potash, and Iron Oxide.

- Cost Impact – $$$$$

Material of Construction

The material of construction the trough is made of can vary depending on the application of the screw conveyor, what it is conveying and how corrosive or abrasive the material is.

- Mild Steel (A36) – Mild steel screw conveyor troughs are suitable for almost every conveying application and are the most commons types used. Example materials to be conveyed in mild steel screw conveyor troughs include Cornmeal, Flour and Frac Sand.

- Cost Impact – $

- Stainless Steel (304 and 316) – Stainless steel screw conveyors are used for applications where contamination or corrosion are a concern. There are also some ideas that stainless steel is a better choice for abrasive and high impact applications because it work hardens. Example materials to be conveyed in stainless steel screw conveyor troughs include Ice, Pet Food, Salt and Spices

- Cost Impact – $$$$$

- Abrasion Resistant Steel (AR235 or AR400) – Abrasion resistant steel screw conveyor troughs are suitable for abrasive materials because the material can be 2-4 times the hardness of mild steel. Example materials to be conveyed in mild steel screw conveyor troughs include Foundry Sand, Potash, and Minerals.

- Cost Impact – $$$$