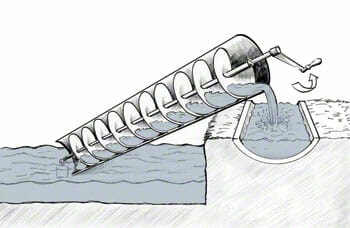

A screw, or sometimes called an auger is the heart of the screw conveyor. The screw is rotated by the screw conveyor drive and pushes the conveyed material forward 1 pitch with every revolution. The screw utilizes theinclined plane principle to move the material. Like a simple ramp but in a spiral, the inclined plane principle provides a mechanical advantage and is considered the simplestform of a machine. The first recorded use of a screw conveyor was by Archimedes around 250 B.C. This basic design is still used today and can be seen in action in every screw conveyor. The screw is the heart of the screw conveyor and understanding it, how it works and how to properly select it are essential to getting the most life with the least downtime out of this essential piece of equipment.

Why is a screw important?

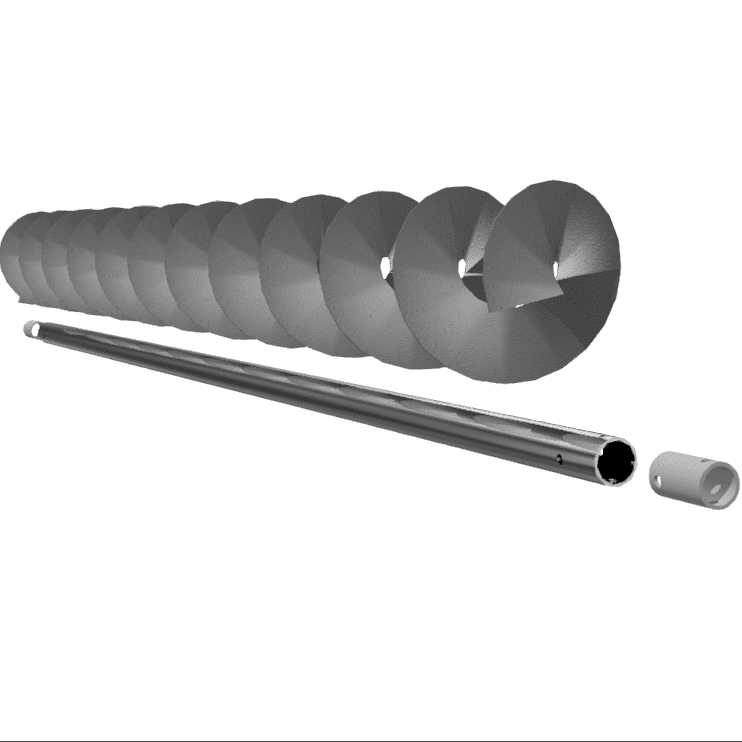

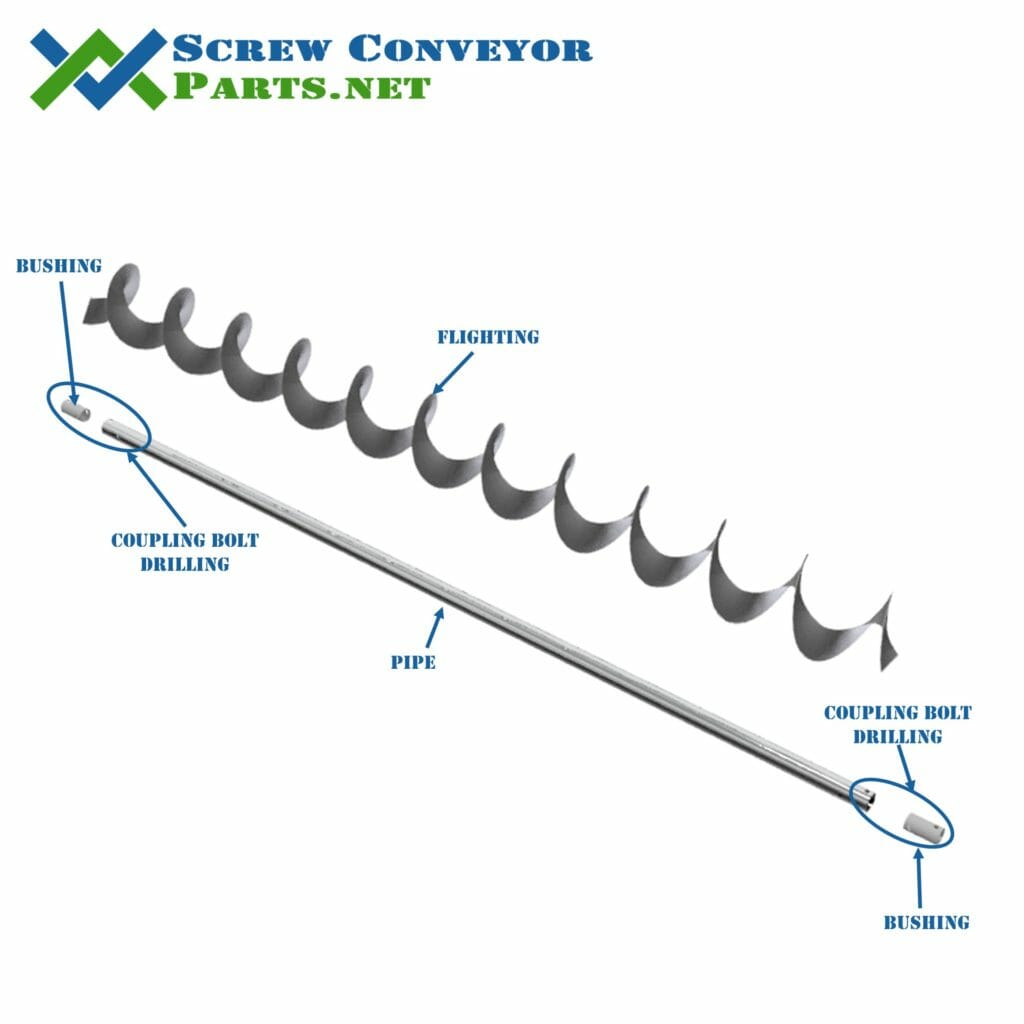

The screw is only one part that makes up a properly design screw conveyor. All the parts of a screw conveyor work together to safely and efficiently convey the material, but nothing is more important than the screw. On the surface, the screw seems simple but the proper design and manufacturing of it is one of the most complex and product specific processes in the industry. The screw is made of rolled or formed plate welded to pipe with steel bushings at each end to accept a drive, coupling or tail shaft. Each end of the pipe/bushing is precision drilled to ensure the proper fit of the coupling bolts trough the screw and the shaft. Of all of these operations the most important, and distinguishing for a screw conveyor manufacturer, is the rolling or forming of the flight and the drilling of the coupling bolt holes. Both of these operations require specialized equipment only found at the heart of the screw conveyor manufacturing process and are what distinguishes a screw conveyor manufacturer from a screw conveyor assembler or distributor. The importance of this process is why Screw Conveyor Parts.NET only works with experienced and knowledgeable screw conveyor manufacturers located in the United States.

What are some of the components of a screw?

In a screw conveyor, the screw is sized by its diameter, shaft size and length. For screws up to standard length, the pipe size is dependent on the shaft size and is schedule40. The standard shaft/pipe combination is adequate tohandle both the torque and deflection of a screw up to the standard length. For lengths above standard, the screw must be evaluated to ensure too much deflection does not occur. For most applications, ¼ is the maximum allowable deflection. All standard length screw use 2 coupling bolts to connect the shaft to the screw. Just like the pipe, the coupling bolt size is dependent on the shaft size. Rarely, does the coupling bolt size change, even when going to longer than standard length screws. In most applications, the inherent strength of the fighting allows for almost any thickness and type to be used with little concern of failure. Thicker fighting is typically used more for abrasion resistance than for a requirement of strength. The same is true for welding, too. The standard 2-sided skip welding of the flighting is sufficient for almost all applications. Continuous welding of the flight is typically used for process or sanitary reasons, not for a requirement of strength. It should be noted that too much weld applied to the pipe will cause distortion and make the screw wobble.

How do I size a screw?

The screw diameter is dependent on several factors, including the capacity of the screw conveyor, the required fill level of the material in the screw, the pitch, and the speed. The calculations for sizing the diameter of a screw are universal and covered in a different topic. The shaft, coupling bolts and pipe sizes are calculated using standard engineering torque, shear and deflection calculations. For most applications, these sizes are dictated by the CEMA standards for each diameter screw. Special applications like long screws, feeders and heavy materials require a more detailed look at these components and any reputable screw conveyor manufacturer can offer assistance. (Click Here for information on screw conveyor manufacturers. Click Here for screw conveyor manufacturer catalogs) In most cases the flighting is standard pitch (meaning the pitch is the same as the diameter) and standard thickness based on the product, not the pipe or shaft size.

..

Standard Shaft/Pipe sizes and Lengths

| Shaft Diameter | Pipe Size | Coupling Bolt Diameter |

| 1″ | 1 1/4″ | 3/8″ |

| 1 1/2″ | 2″ | 1/2″ |

| 2″ | 2 1/2″ | 5/8″ |

| 2 7/16″ | 3″ | 5/8″ |

| 3″ | 3 1/2″ | 3/4″ |

| 3 7/16″ | 4″ | 7/8″ |

Standard Nominal Screw Lengths

| Diameter | Standard Nominal Length |

| 4″. 6″, 9″, 10″ | 10ft |

| 12″, 14″, 16″, 18″, 20″, 24″ | 12ft |