Screw conveyors, like any other mechanical equipment, are driven by an electric motor. The motor provides a lot of power (HP) but very little torque (In-lbs). The power is effective at conveying the bulk material in the screw conveyor but can do little to start the screw or rotate it. Each screw conveyor motor is connected, directly or indirectly to a speed reducer, also called a gear reducer or just reducer. The reducer takes the speed of the motor and reduces it to the required speed of the screw conveyor, usually 20-80 revolutions per minute (RPM). The relationship between speed, power and torque is due to the following formula. The combination of motor and reducer is commonly referred to as the screw conveyor drive.

Screw conveyors, like any other mechanical equipment, are driven by an electric motor. The motor provides a lot of power (HP) but very little torque (In-lbs). The power is effective at conveying the bulk material in the screw conveyor but can do little to start the screw or rotate it. Each screw conveyor motor is connected, directly or indirectly to a speed reducer, also called a gear reducer or just reducer. The reducer takes the speed of the motor and reduces it to the required speed of the screw conveyor, usually 20-80 revolutions per minute (RPM). The relationship between speed, power and torque is due to the following formula. The combination of motor and reducer is commonly referred to as the screw conveyor drive.

Torque = (HP x 63,025) / RPM

There are lots of different combinations of motors and reducers available to drive a screw conveyor. In addition, there are lots of different ways to connect the drive to the screw conveyor. Over time, a few drive configurations have emerged and become the most common, mostly in part to the standardization of screw conveyors. With CEMA standard screw conveyor diameters and shaft sizes, drive manufacturers have been able to create standard configurations specifically for screw conveyors, therefor continuing to lower the overall costs of screw conveyors when compared to other conveying technology.

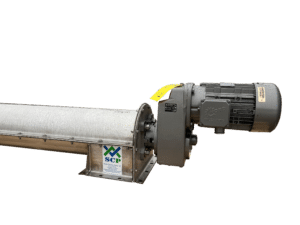

Screw Conveyor Adapter

Although a screw conveyor adapter is not a drive itself, it is worth discussing individually since it applies to all styles of screw conveyor drives. The screw conveyor adapter plays off the standardization of the screw conveyor. The adapters are specifically designed to bolt to CEMA standard screw conveyor trough ends and CEMA standard screws. Screw conveyor adapters come with the adapter to mount the drive to the screw conveyor, integral shaft seal and driveshaft. These adapters are highly versatile, durable and cost effective. All the major drive manufactures make a screw conveyor adapter and is an optional add-on accessory.

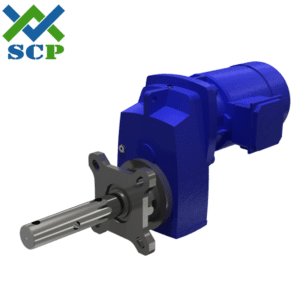

Compact Multi-Ratio Gear Reducers

These types of gear reducers are compact, available in multiple ratios to allow the precise speed reduction to be selected to get the desired screw conveyor speed. These styles of drives are available in several configurations including parallel, right angle, integral motor and C-Face motor. This style is the most cost-effective screw conveyor drive available with parallel and integral motor being lowest cost and most common of these. These drives are extremely effective for screw conveyors and have proved to be very reliable. The main disadvantage is this style of screw conveyor drives are since they are so configurable there are thousands of combinations meaning each one is custom built for a specific application. Because they are custom built, they are not stock and if one fails a replacement must be built, instead of being in stock. Some of the major manufacturers are Nord, SEW, Dodge and Sumitomo.

Modular Gear Reducers

These types of gear reducers are modular in design and offered in far fewer ratios than a multi-ratio gear reducer. Because of this, modular gear reducers are stocked at distributors across the country. Because of the few gear reduction ratios available a sheave and belt drive combination must be used to get the desired screw conveyor speed. The two biggest advantages of this style of screw conveyor drive are the availability of the components and the serviceability of the gear reducer. Unlike the multi-ratio gear reducers where the compact design requires special tooling and procedures to service, modular gear reducers are built to be serviced with rebuild kits available to rebuild or replace all the major components. In addition, many plants like to standardize on 2 or 3 different models so stocking replacements is easier. The major disadvantages are they cost about 50% more than the multi-ratio gear reducers and they have belts which will wear and require replacement. Major manufacturers of modular gear reducers are Dodge and Falk/Rexnord.

For help sizing and buying screw conveyor drives shop our standard Nord screw conveyor drives or contact one of our engineers. [email protected] or (682) 231-1228