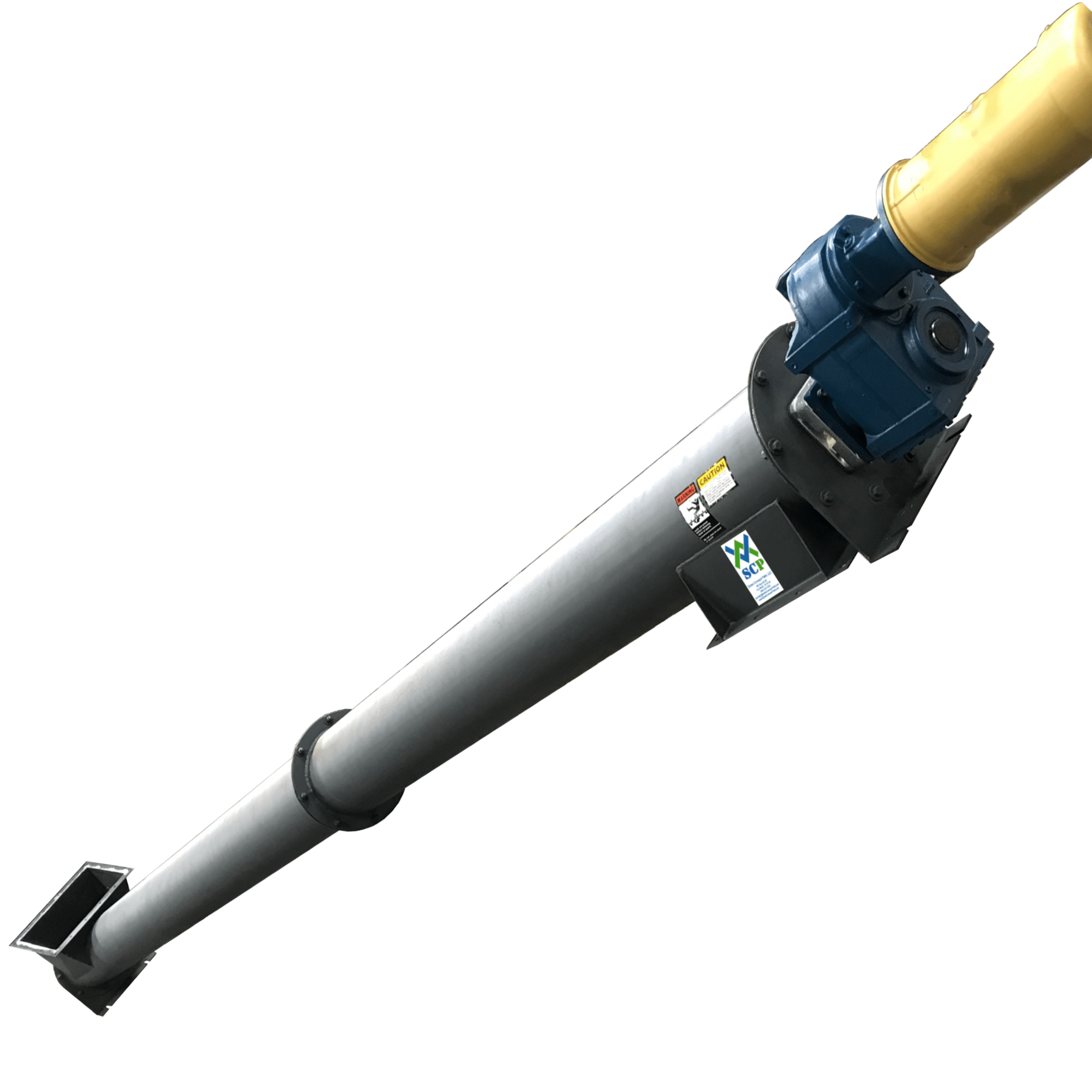

Screw conveyors are extremely versatile and therefore called to do a lot in a modern bulk material handling process. From the mundane of a simple horizontal screw conveyor to the more extravagant thermal screw, screw conveyors are adapted to large mix of applications due to their reliability, enclosed design and affordability. One of the more common and more overlooked applications is using a screw conveyor to meter bulk material from a bulk bag, hopper, or silo to an elevated process. This application is referred to as an inclined screw feeder. With a screw conveyor or feeder, we think of it as inclined when it is 10deg or more. At 10deg and above a screw conveyor becomes less efficient and is affected by the angle, pitch and the trough shape. All of these factors will affect the feed rate and contribute to a successful inclined screw feeder application.

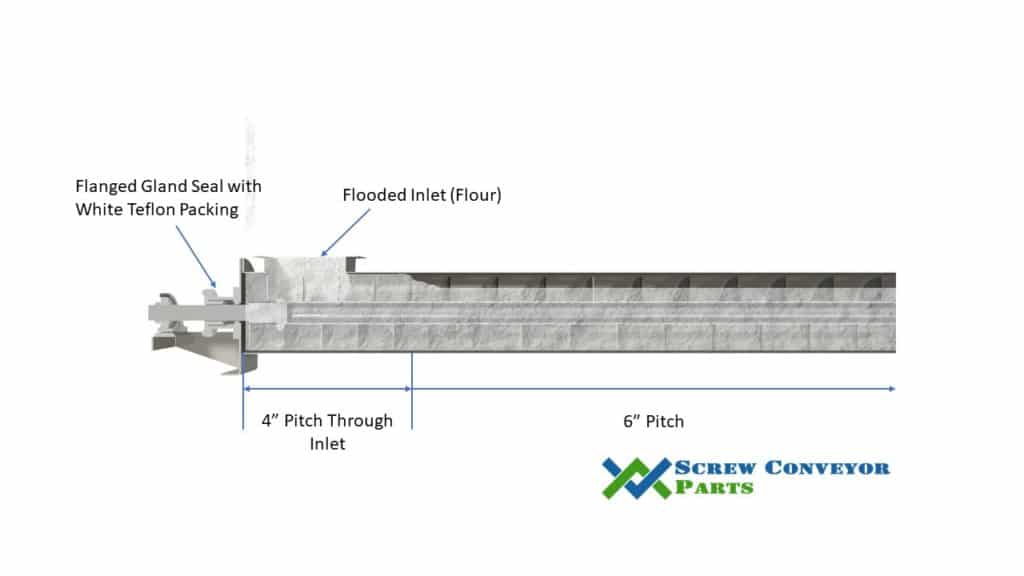

The most common style of inclined screw feeder is when the feeder is connected, or integral, with the hopper, bin, or silo. This design is the most economical and allows the incline screw feeder to meter the flow from the inlet and convey it to the desired height. When designing this type feeder the trough loading will be at 100% through the inlet and the flighting needs to be designed to allow for a small amount of relief through the rest of the feeder. Usually, having ½ pitch through the inlet and 2/3 through the balance will provide the small amount of relief the bulk material needs to ensure there is no compaction causing the trough to get plugged. Using a single feeder/conveyor, the discharge height is limited by the maximum allowable deflection of the screw and usually results in a max height of about 8ft for small screw feeders and as high as 15ft for larger screw feeders.

A single incline feeder/conveyor design is an ideal solution when the length of the screw is short enough it does not require a hanger for support. When a hanger is required the bulk material flow path is obstructed. To go under the hanger the trough loading needs to be under about 30% and this can be tough when the trough loading starts at 100% in the inlet.

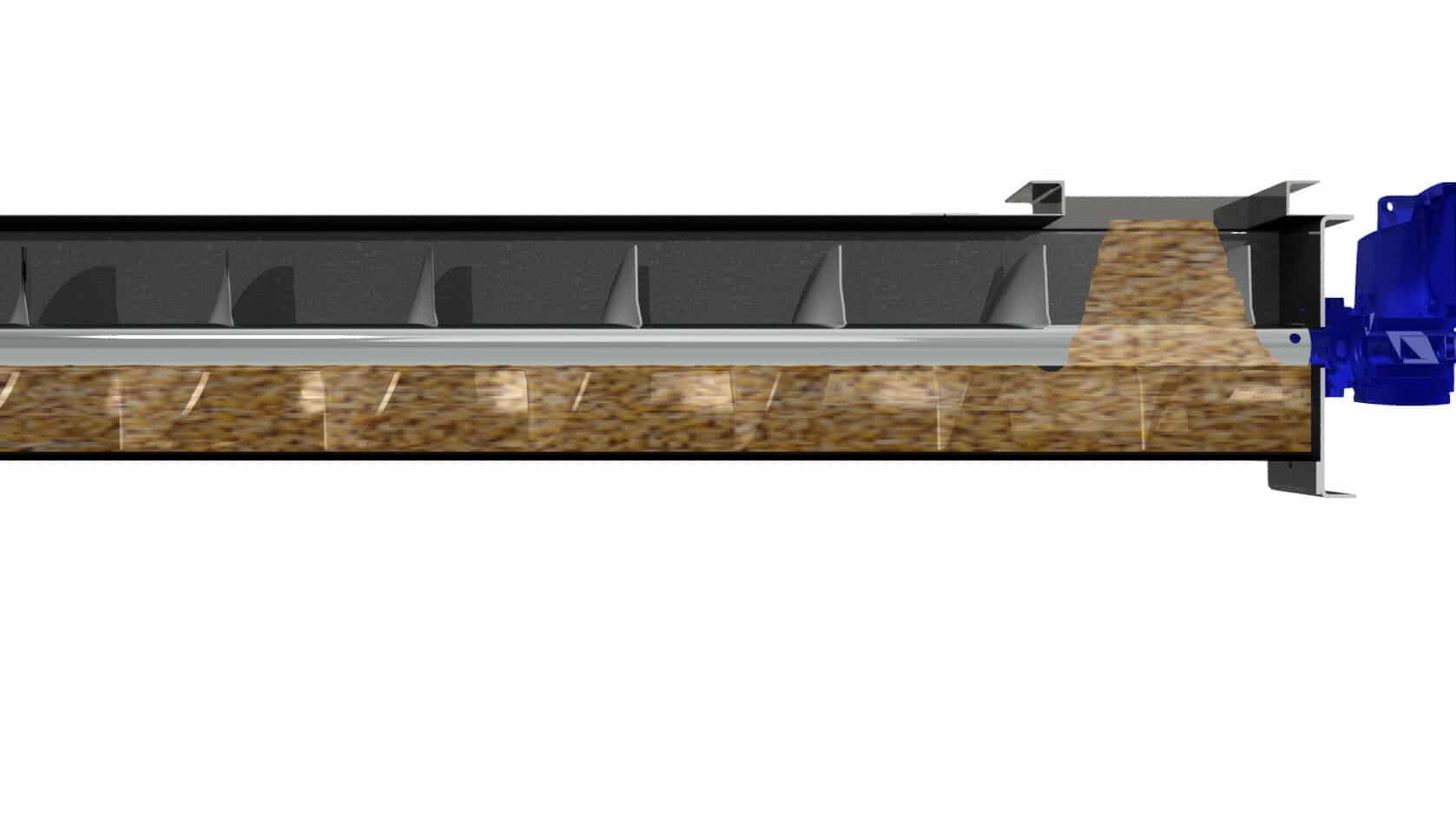

The second style of incline screw feeder arrangement is using a small horizontal feeder to feed an inclined screw conveyor. This style is ideal when the length of the incline screw requires a hanger. The horizontal screw feeder can be specifically designed to meter the bulk material and the incline screw conveyor can be specifically designed to conveyor the material. Using this configuration, the discharge height of the screw feeder/conveyor system has almost no limitations.