Screw conveyors are used in a wide variety of applications from agriculture to chemicals to wastewater and even food applications. Whether used in human food applications or pet food applications, each industry, customer and even each plant has a different idea of the finish requirements for screw conveyors. Even the step in the food making process can widely influence the finish requirements of the screw conveyor. Unfortunately, there is no universally accepted standards for the finish requirements of the screw conveyor by any of the major regulatory agencies like CEMA or the FDA.

With so much ambiguity in the term “food grade” or “sanitary” it is hard to use these terms as any universal specification. Instead, the screw conveyor designer has to know where the screw conveyor is being used in the process and what product is being conveyed to start to ask the right questions about the finish requirements. The main areas of concern are the material of construction, surface finish, weld finish, allowance cracks and cervices gasketing, shaft seals and coupling bolts. Below are four broad levels for screw conveyor finish, but many other factors come into play and of course, as the requirements go up so too do the costs.

Level 1 –Carbon Steel Screw Conveyor – Standard Construction

This is a basic screw conveyor construction with no attention paid to finish.

- Material of Construction: Carbon Steel

- Surface Finish – none/mill, 1-coat of enamel paint

- Weld Finish – As laid, non-continuous

- Cracks and Crevices – Allowed

- Gasketing – Non-food grade, open cell.

- Coupling Bolts and Hanger Bearings Allowed

- Shaft Seals – Any Screw Conveyor Shaft Seal

Level 2 –Carbon Steel Screw Conveyor – No Cracks or Crevices

Used in dry food applications – The main concern here is eliminating large openings where bugs can hide and be hard to inspect and clean out.

- Material of Construction: Carbon Steel

- Surface Finish – none/mill, 1-coat or 2-coats of White Enamel

- Weld Finish – As laid, continuous.

- Cracks and Cervices – Large crevices not allowed, some cracks and crevices allowed

- Gasketing – Food grade, closed cell

- Coupling Bolts and Hanger Bearings Allowed

- Shaft Seals – Any Screw Conveyor Shaft Seal, Usually Stainless Steel

Level 3 –Stainless Steel Screw Conveyor – No Cracks or Crevices

Used in dry food applications – The main concern here is eliminating large openings where bugs can hide and be hard to inspect and clean out.

- Material of Construction: 304 Stainless Steel

- Surface Finish – Exterior bead blasted to uniform finish.

- Weld Finish – As laid, Continuous

- Cracks and Cervices – Large crevices not allowed, some cracks and crevices allowed

- Gasketing – Food grade, closed cell

- Coupling Bolts and Hanger Bearings Allowed

- Shaft Seals – A mechanical shaft seal

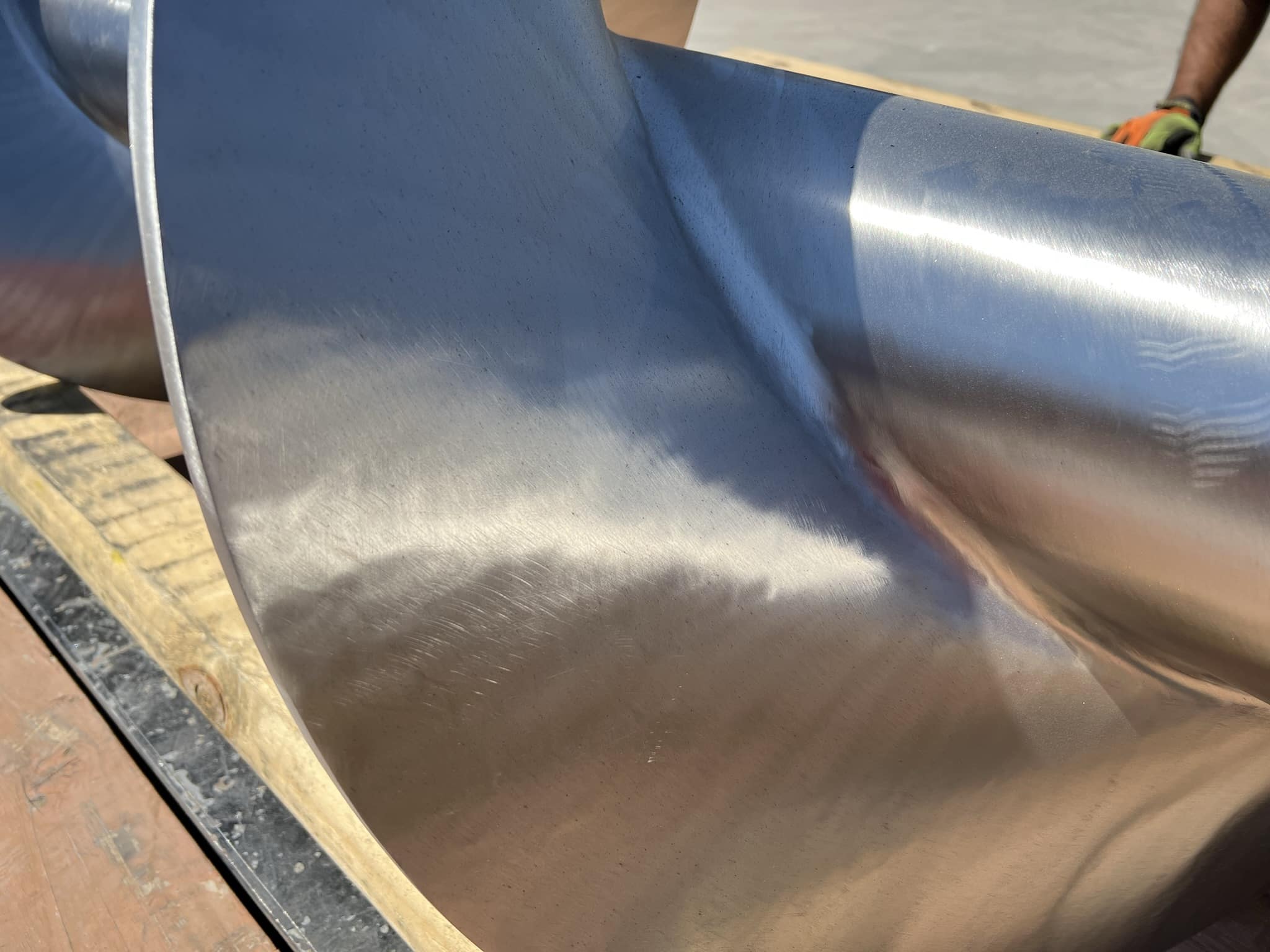

Level 4 –Stainless Steel Screw Conveyor – No Cracks or Crevices, Polish Finish

Used in dry and wet applications where microbial growth needs to be minimized and/or eliminated

- Material of Construction: 304 Stainless Steel

- Surface Finish – Exterior bead blasted to uniform finish.

- Weld Finish – 120Grit Polish, Continuous

- Cracks and Cervices – Not allowed.

- Gasketing – Food grade, closed cell

- Coupling Bolts and Hanger Bearings Not allowed

- Shaft Seals – A mechanical shaft seal

CEMA Weld Finishes

CEMA does have requirements for weld finish but these only apply the welds and do not give any direction on the steel finish requirements or the allowance of cracks and cervices. Many people confuse the CEMA weld finishes as sanitary/food grade requirements. To properly design a screw conveyor for sanitary/food grade environment the entire screw conveyor design must be considered, not just the screw welds.